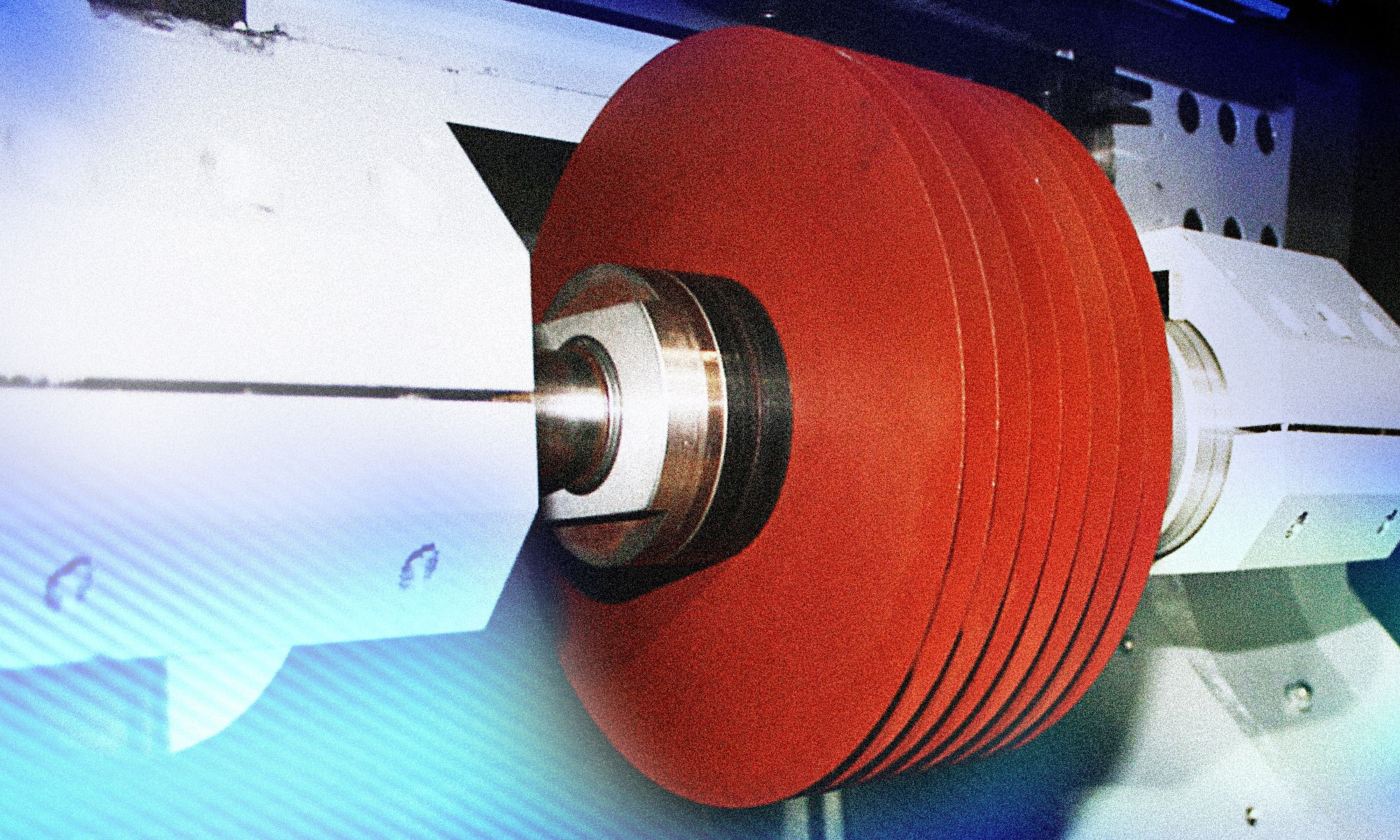

Dicing ferrous and non-ferrous metals poses several challenges due to the unique properties of these materials. The slicing and dicing process for these types of materials require appropriate applications, customized process, temperature control, specialized tooling and set up. Within this document, we will delve into the intricacies of cutting both ferrous and non-ferrous materials. At MTINC, our expertise lies in the realm of high-precision gang dicing saws designed to proficiently handle the slicing and dicing of both ferrous and non-ferrous materials.

Ferrous Materials:

Ferrous metals, particularly hardened steel alloys, pose challenges due to their exceptional hardness and toughness. Traditional cutting methods struggle to make an impact, necessitating specialized tools capable of withstanding such hardness without succumbing to wear. The cutting process induces heat, a critical concern for ferrous metals susceptible to heat buildup. This heat can lead to tool wear, alterations in material properties, and potential precision issues. The inherent hardness of ferrous materials accelerates tool wear, demanding frequent changes and maintenance, incurring additional costs for consistent and accurate cuts. Dicing ferrous materials often results in burrs on cut edges, making achieving a smooth surface finish challenging. While additional processes may be required to eliminate burrs and enhance overall results, effective strategies exist to minimize burrs. The dicing process introduces residual stresses into ferrous metals, particularly near the cut, necessitating careful management to prevent distortion, warping, or other undesired effects in finished components. Contamination concerns arise as particles generated during cutting may affect the performance or properties of ferrous metals. Consequently, precautions must be taken to avoid introducing foreign materials. Given that ferrous metals are frequently used in applications with tight tolerances and high precision requirements, meeting these criteria during the dicing process demands advanced cutting technologies and meticulous process control. The complexity of choosing the right cutting tools and optimizing parameters for diverse ferrous alloys requires a tailored approach. Manufacturers address these challenges through a combination of advanced cutting technologies, specialized tools, and expertise in materials science and machining. This often involves substantial investments in state-of-the-art equipment and the employment of skilled professionals to overcome the unique difficulties associated with dicing ferrous metals.

Non-Ferrous Materials:

Non-ferrous metals, exemplified by aluminum and copper, exhibit characteristics of being softer and more ductile compared to their ferrous counterparts. While this imparts certain advantages, such as enhanced malleability, it also introduces challenges during the dicing process, such as the potential for deformation and the formation of burrs. The heightened thermal conductivity inherent in many non-ferrous metals contributes to rapid heat dissipation during cutting, impacting process efficiency and potentially altering material properties. Adhesion to cutting tools, particularly prevalent with traditional methods, can lead to tool wear, diminished precision, and the need for frequent maintenance. Some non-ferrous metals, like aluminum, possess abrasive properties that can accelerate tool wear, necessitating the use of cutting tools capable of withstanding abrasion while maintaining sharpness. Additionally, susceptibility to oxidation, especially when exposed to air during cutting, introduces challenges to achieving an optimal surface finish. Addressing oxidation-related issues often requires supplementary processes. During the dicing process, non-ferrous metals may produce long, stringy chips that have the potential to interfere with the cutting operation. Efficient chip evacuation systems become imperative to maintaining a smooth cutting process. The softer nature of non-ferrous metals presents challenges in achieving high precision during dicing. Delicate components may be more prone to deformation, requiring meticulous handling and thoughtful tool selection. Given the diverse range of materials encompassed by non-ferrous metals, each with varying properties, the dicing process must demonstrate adaptability to different alloys, thicknesses, and compositions. This necessity underscores the importance of employing flexible cutting solutions. Contamination concerns arise as foreign particles generated during cutting can impact the performance of non-ferrous metals. Thus, preventive measures are essential to avoid introducing contaminants that could compromise the material’s functionality. Selecting appropriate cutting tools and optimizing cutting parameters for different non-ferrous alloys demand careful consideration. Customizing the dicing process to align with the specific characteristics of each material becomes crucial in ensuring precision and efficiency. To address these challenges in dicing non-ferrous metals, manufacturers leverage advanced cutting technologies, employ specialized tools, and tap into expertise in materials science and machining. The implementation of precise control systems and the employment of skilled professionals are common practices to ensure the efficient and accurate dicing of non-ferrous metals.

Blog | Dicing Ferrous and Non-Ferrous Material