The advantages of truing your cutting wheels are immeasurable and have a direct impact on the quality, repeatability, and reliability of your wheel and dicing saw. Specific advantages include maintaining a proper square wheel profile, which directly contributes to cleaner cuts, less chipping on the surface next to the cut, and higher accuracy cuts, as well as improved wheel life and reliability.

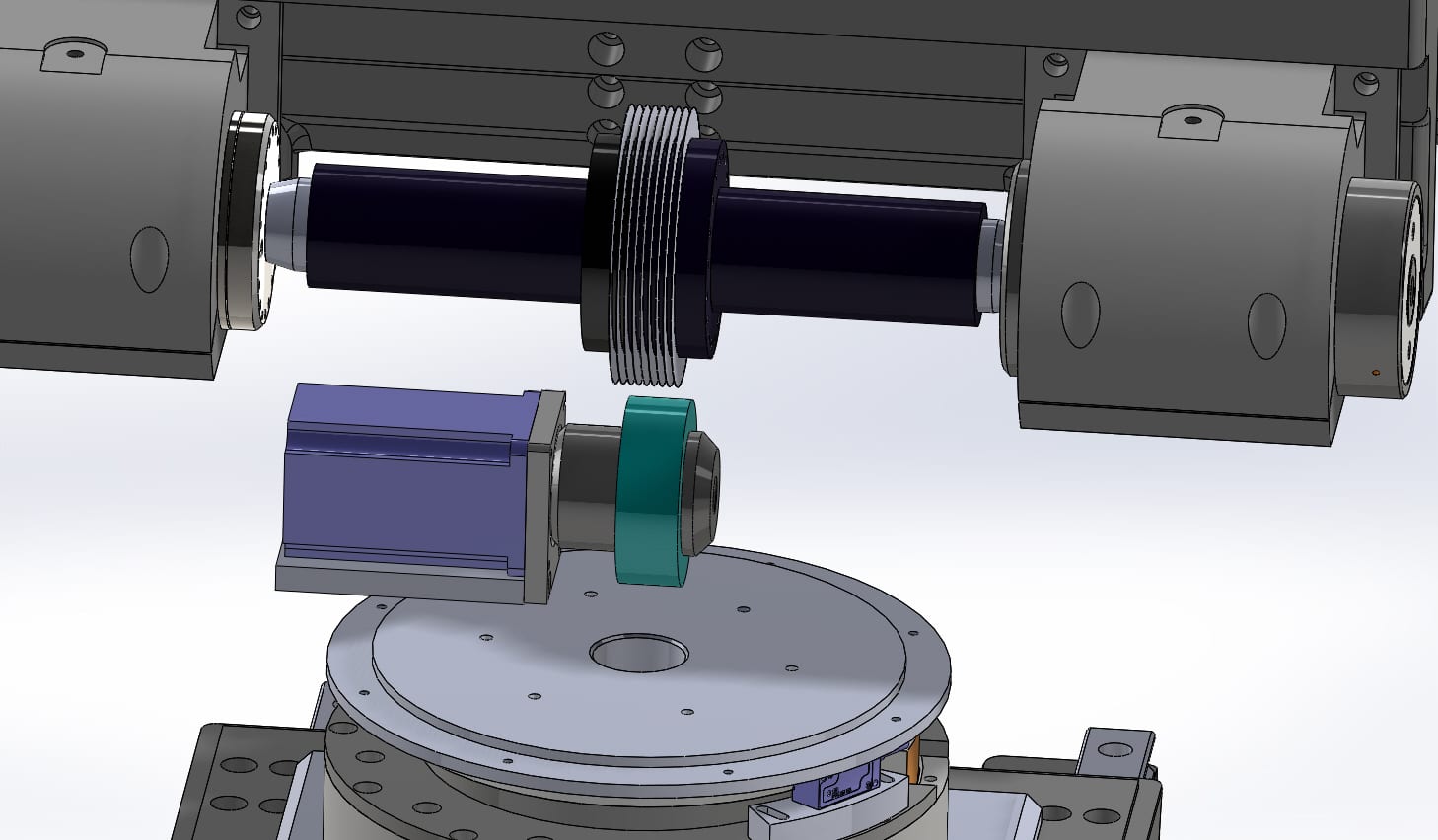

Designed by slicing and dicing engineers for seamless integration into any MTINC dicing saw, our On-Line truing system is a dynamic way to set up and true arbors directly in the machine to ensure the optimal truing and wheel performance. It allows customers to have multiple arbors ready to dice a wide variety of parts with minimal downtime for wheel conditioning, allowing them to get the most production out of their dicing saws and wheels.

The MTINC Off-Line Gang Truing System is tailored to service gang dicing saws. It is a dynamic way to set up true arbors before the cutting process, allowing the customer to have multiple arbors ready to dice various parts.

CONTRACT CUTTING

With over 40 years of experience, MTINC Machines has developed a reputation as an Industry Leader for high precision CNC machine slicing and dicing services. By providing a solution centric approach to meet the needs of customers across a wide range of industries, our high precision and power dicing saws provide the highest quality cutting services in the industry at sub-micron tolerances with extreme repeatability and reliability. We actively improve our customers products by offering unparalleled insight into slicing and dicing process development; with our wealth of experience in the industry, we can provide the latest cutting-edge technology to maximize productivity, efficiency, and ensure your product is of the highest standards and quality.