PRECISION RAILS & BALLSCREWS

Replace old, worn-out axis with a new or rebuilt axis for improved machine performance and improved accuracy of cuts

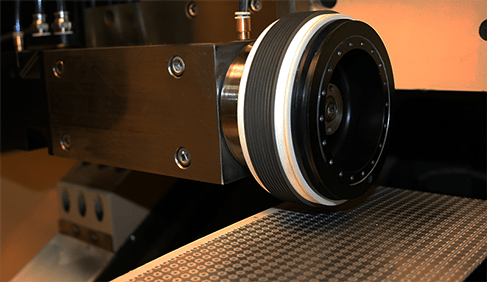

GANG SPINDLES

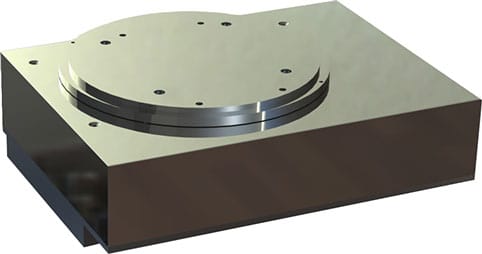

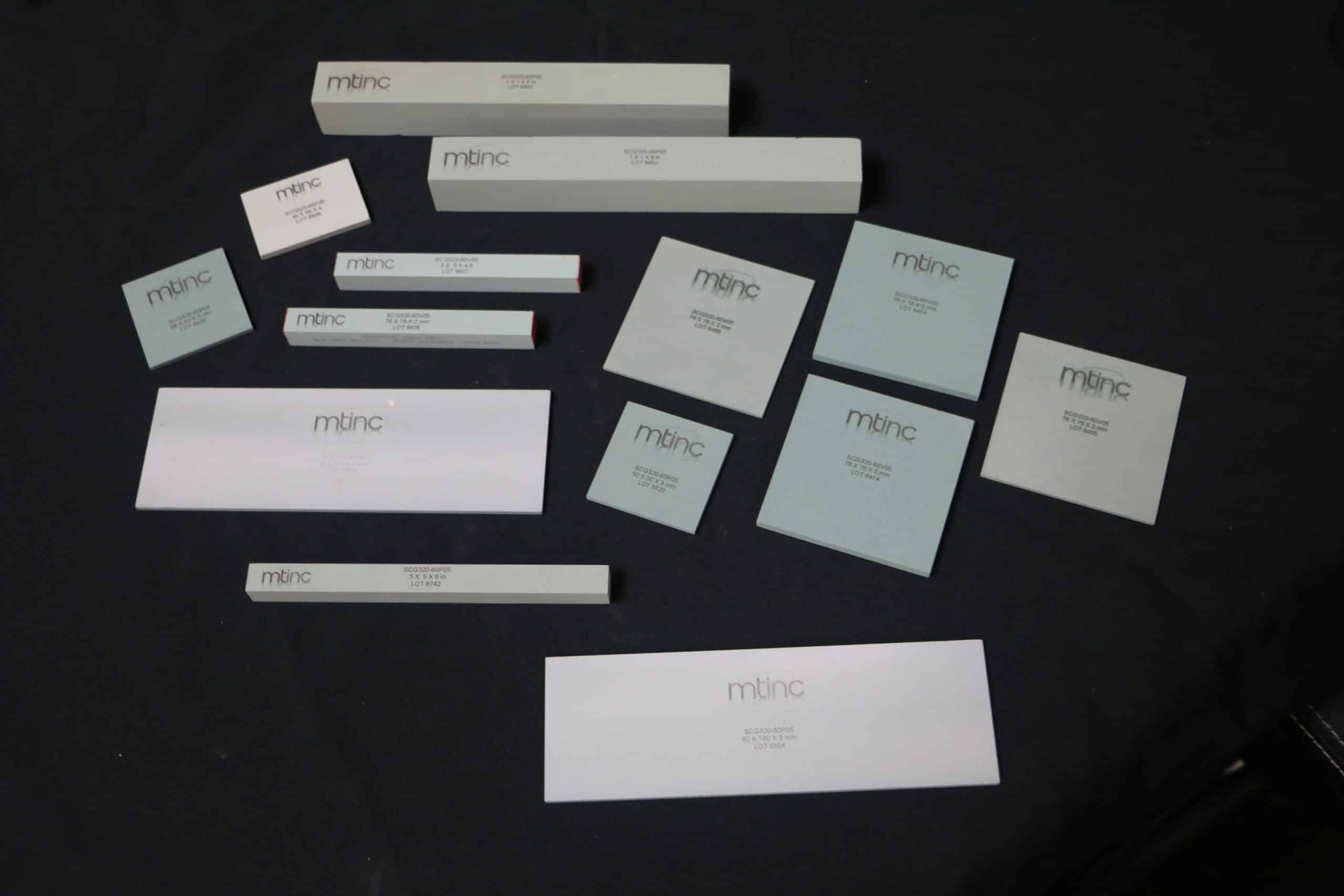

MTINC Precision Alignment Table

MTINC’s Precision Alignment Table sets the industry standard for engineering excellence, combining custom craftmanship and superior accuracy to guarantee top-tier quality results.

FANUC SPARE PARTS

Spindles, Spindle Drives / Amplifiers

Custom Spindle Drive Pulley’s and Belts for maximum machine Torque and Speed

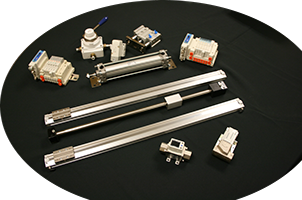

PNEUMATIC SYSTEM

Complete Pneumatic System upgrades for any Mtinc or Mti Dicing Saw

High Speed Precision Spindles

Spindles, Spindle Drives / Amplifiers

Mtinc has a wide variety of precision spindles and spindle drives for all models of Mtinc and Mti Dicing Saws. We provide many models of spindle drives, including mechanical and air-bearing spindles, to all makes and models of dicing saws; as well as spindle upgrades. All Mtinc spindles are designed in Solidworks and put through an extremely rigorous test process prior to being sold and installed at the customer’s facility.

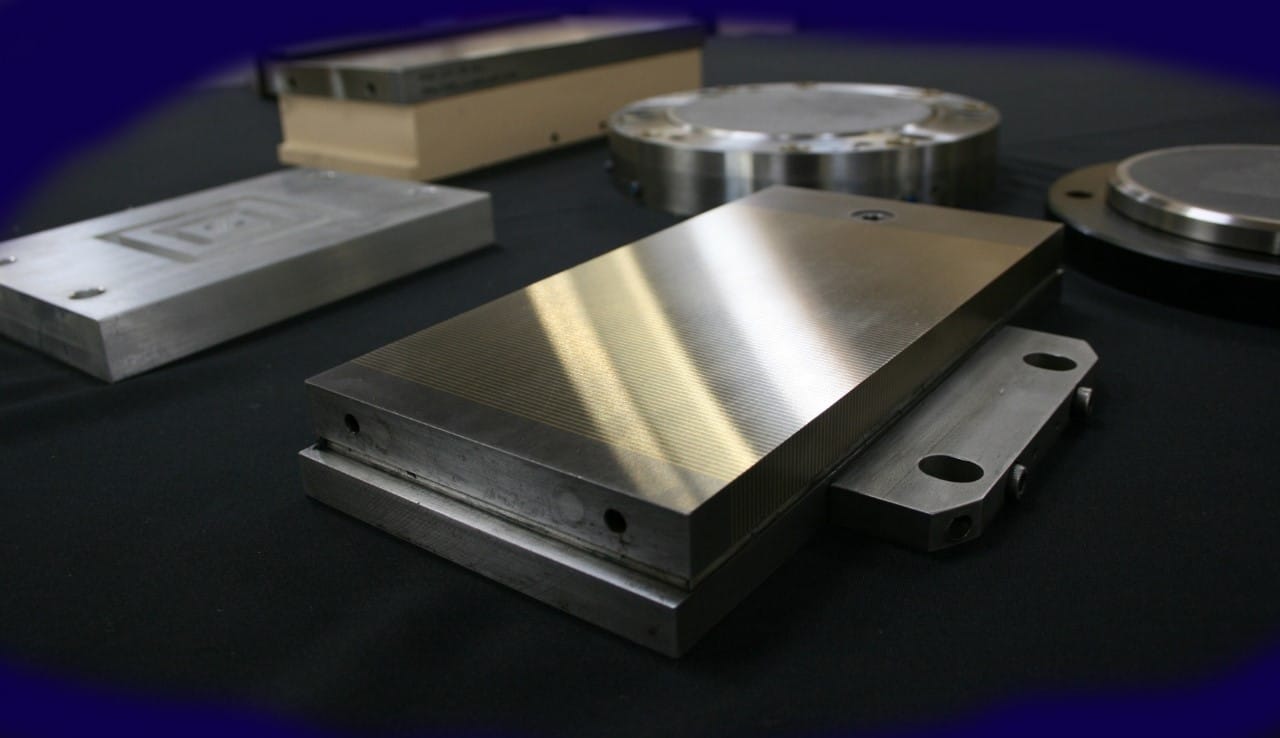

VACUUM CHUCK

MTInc can provide your machines with vacuum and magnetic chucks to achieve complete adhesion and stability for your parts. MTInc chucks can be swiftly and efficiently mounted directly onto the X-axis.

DRESSING STICKS

Dressing Sticks and Boards for Diamond and CBN Dicing Wheels (Super finishing abrasives)

Diamond and CBN Dicing wheels require frequent dressing to maintain peak performance and tool life. If this is not done, the diamond tool will glaze over and cause the cutting action to slow down and change from grinding to tearing, creating excessive heat, and leading to the diamond tool and part failure. Glazing is caused by the metal bond (which bonds the diamond abrasives to each other and to the tool) overheating and coating the diamond abrasive. As the tool glazes over, the metal bond becomes the cutting material as opposed to the diamond.