Gang dicing BK7 and lithium niobate involves the simultaneous cutting or separation of multiple optical components made from these specific materials. BK7 is a borosilicate crown glass often used for optical components, while lithium niobate is a crystalline material with unique optical and electro-optic properties. Here’s an overview of key aspects related to gang dicing BK7 and lithium niobate:

- BK7 Optical Glass:

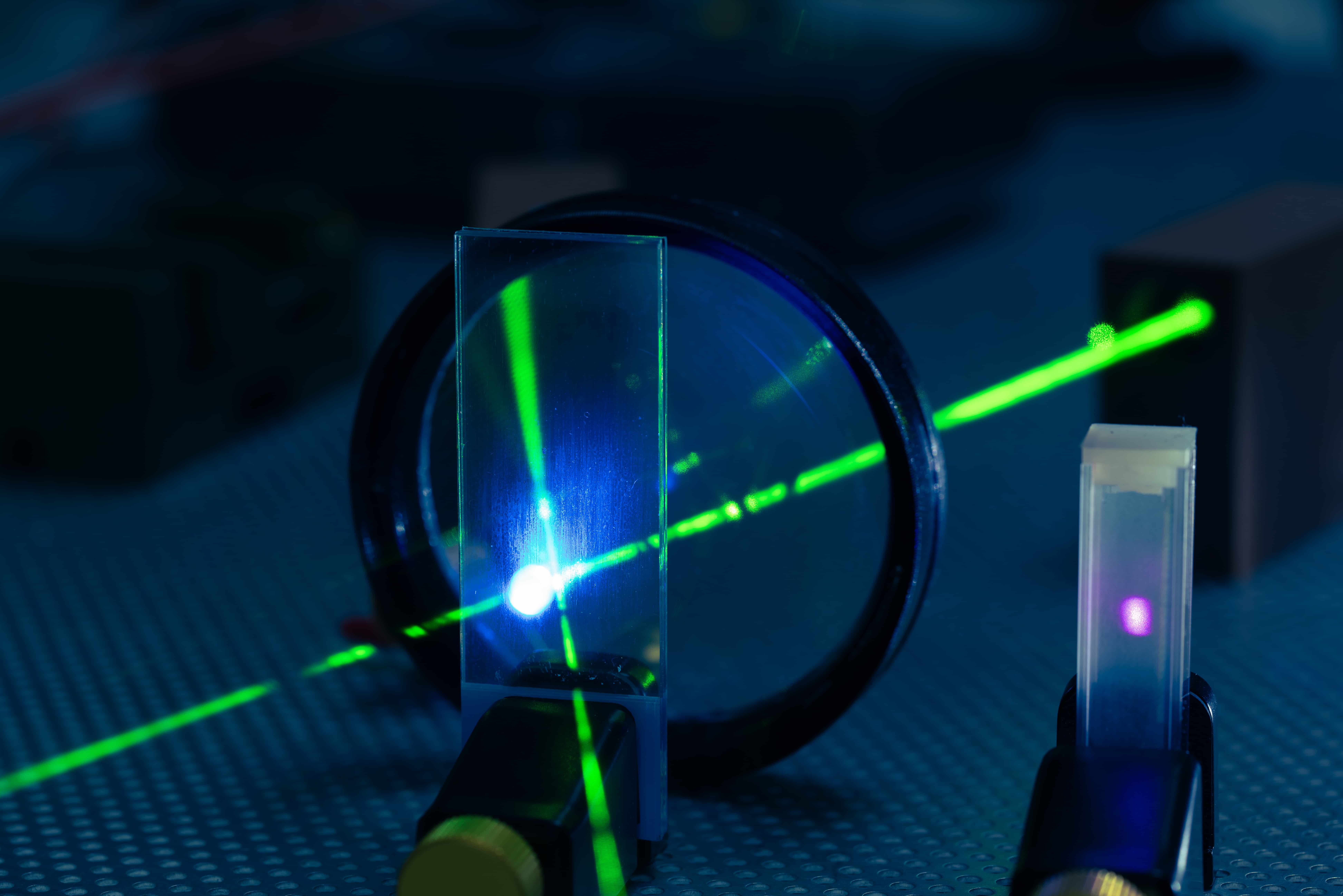

BK7 is a type of optical glass known for its excellent optical properties, including high transmittance in the visible and near-infrared spectrum. It is widely used for lenses, prisms, and other optical components. - Lithium Niobate (LiNbO3):

Lithium niobate is a crystalline material with ferroelectric and electro-optic properties. It is used in various optical and electronic applications, such as modulators, waveguides, and nonlinear optics. - Dicing Techniques:

Gang dicing of BK7 and lithium niobate can be performed using customized diamond wheels. The selection of wheels depends on material properties, precision requirements, and the desired characteristics of the optical components. - Blade Dicing:

Blade dicing utilizes a rotating blade to cut through the BK7 or lithium niobate material, separating multiple optical components simultaneously. This method is suitable for materials with moderate hardness. - Material Considerations:

The choice of dicing technique depends on the specific material properties of BK7 and lithium niobate. These materials may have different hardness levels, and the dicing method must consider avoiding damage to the optical components. - Multiple Components in One Pass:

Gang dicing allows for the simultaneous cutting of multiple optical components from a larger substrate, increasing efficiency and throughput in optical component manufacturing. - Precision Requirements:

Precision is critical in gang dicing BK7 and lithium niobate to ensure that each separated optical component meets tight tolerances. This is essential for maintaining optical clarity and performance. - Die Layout and Spacing:

The arrangement of optical components on the substrate, known as the die layout, and the spacing between components are essential considerations in gang dicing to prevent damage and ensure accurate separation. - Wafer Mounting:

Before gang dicing, the optical substrate is often mounted on a dicing tape or adhesive film to facilitate the dicing process and prevent damage to the components. - Post-Dicing Processes:

After gang dicing, there may be additional processes such as polishing, coating, or assembly to prepare the individual optical components for integration into optical systems or devices. - Applications:

Gang dicing of BK7 and lithium niobate is used in the production of various optical components, including lenses, prisms, modulators, waveguides, and other devices for applications in imaging, telecommunications, and photonics.

In summary, gang dicing BK7 and lithium niobate is a crucial step in the manufacturing of optical components, allowing for the simultaneous separation of multiple components from a larger substrate. The choice of dicing technique, precision considerations, and material properties are essential factors in ensuring the quality and performance of the individual optical components produced.