Description

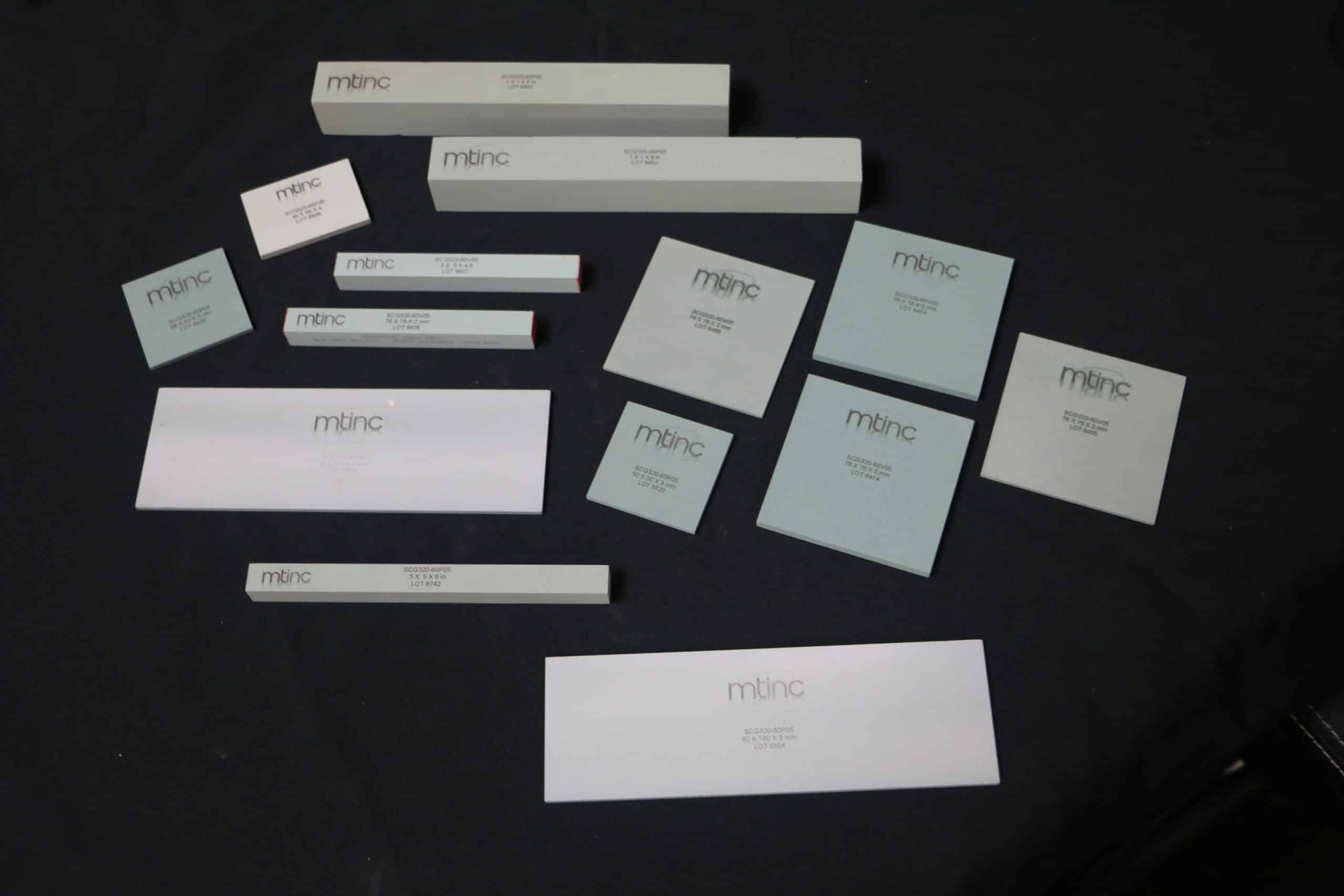

Dressing Sticks and Boards for Diamond and CBN Dicing Wheels (Super finishing abrasives)

Diamond and CBN Dicing wheels require frequent dressing to maintain peak performance and tool life. If this is not done, the diamond tool will glaze over and cause the cutting action to slow down and change from grinding to tearing, creating excessive heat, and leading to the diamond tool and part failure. Glazing is caused by the metal bond (which bonds the diamond abrasives to each other and to the tool) overheating and coating the diamond abrasive. As the tool glazes over, the metal bond becomes the cutting material as opposed to the diamond.

To prevent the diamond tool from glazing over, frequent use of dressing sticks and boards is required. The dressing process wears away the top layer of metal bond and worn diamond abrasive to expose a fresh layer of sharp diamond. With the sharp diamond exposed, the diamond tool is once again able to cut freely with less heat and maintain the proper tool life.

Dressing sticks and boards come in many different types and sizes. Depending on the type of blade and material being diced, Silicon Carbide or Alumina Oxide are the most common types of dressing sticks.

All Dressing Sticks and Boards are available in many different sizes and shapes.

Note: Dressing sticks and boards are not optional with the use of diamond tooling, they are required.