by Steve Rovinsky | Apr 10, 2024 | Uncategorized

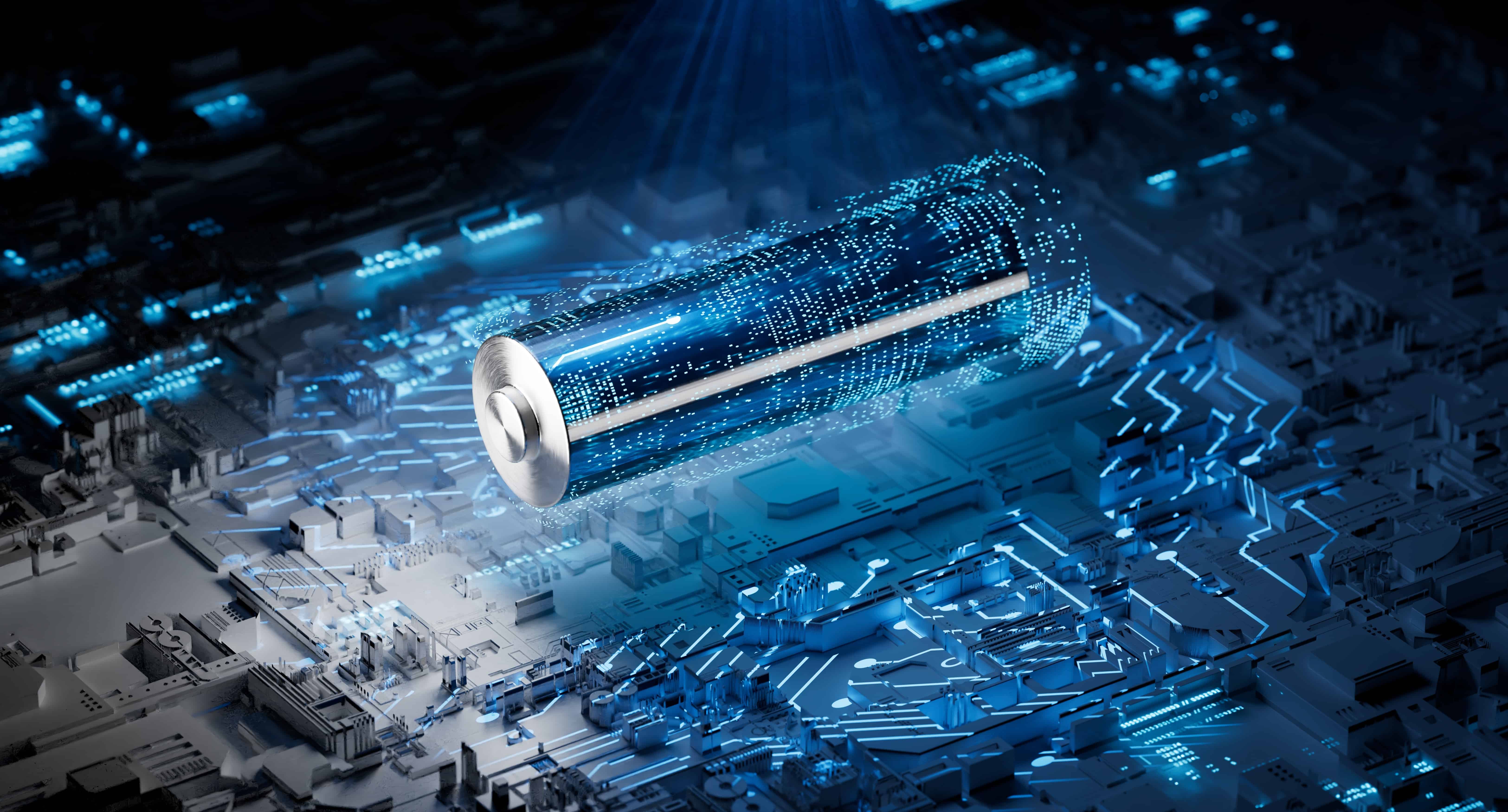

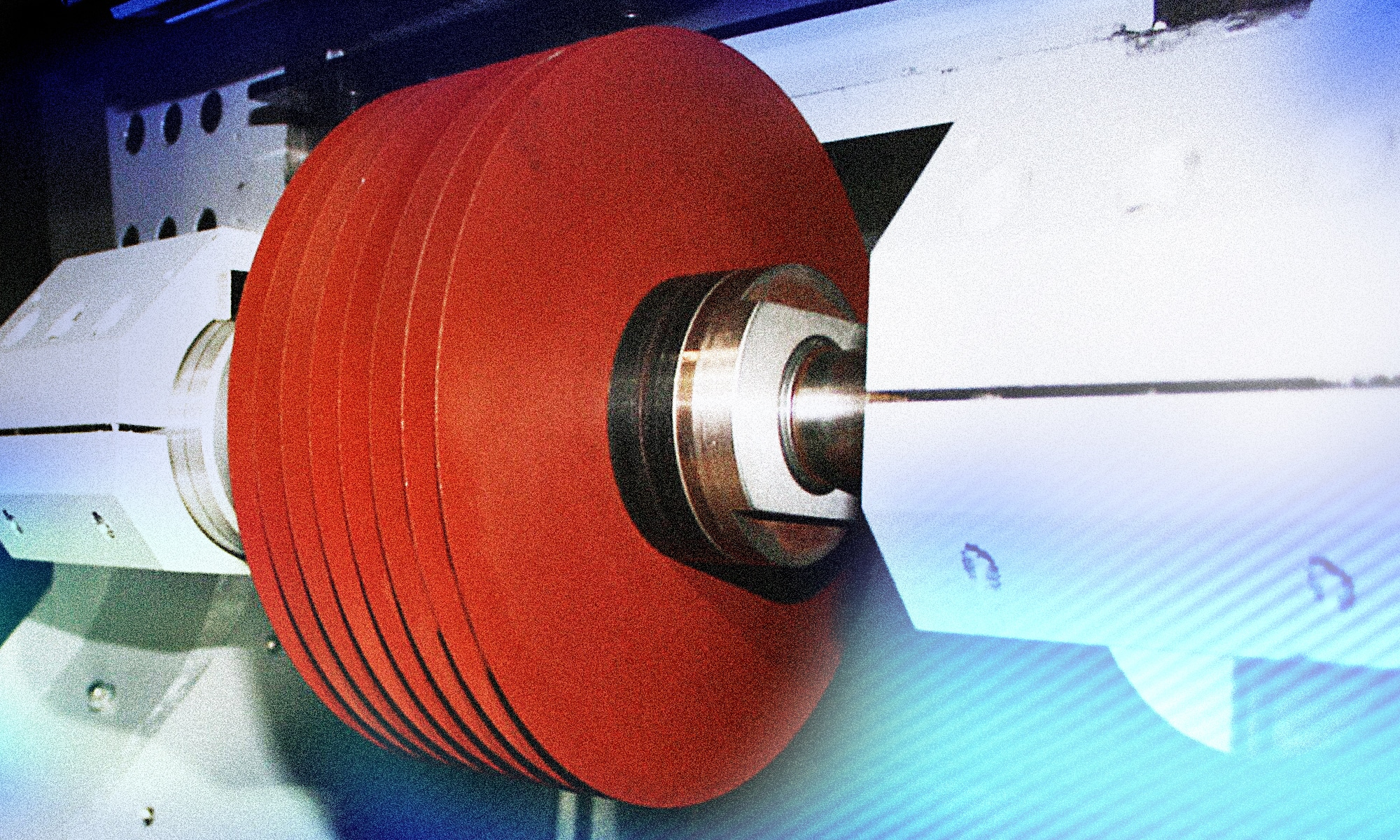

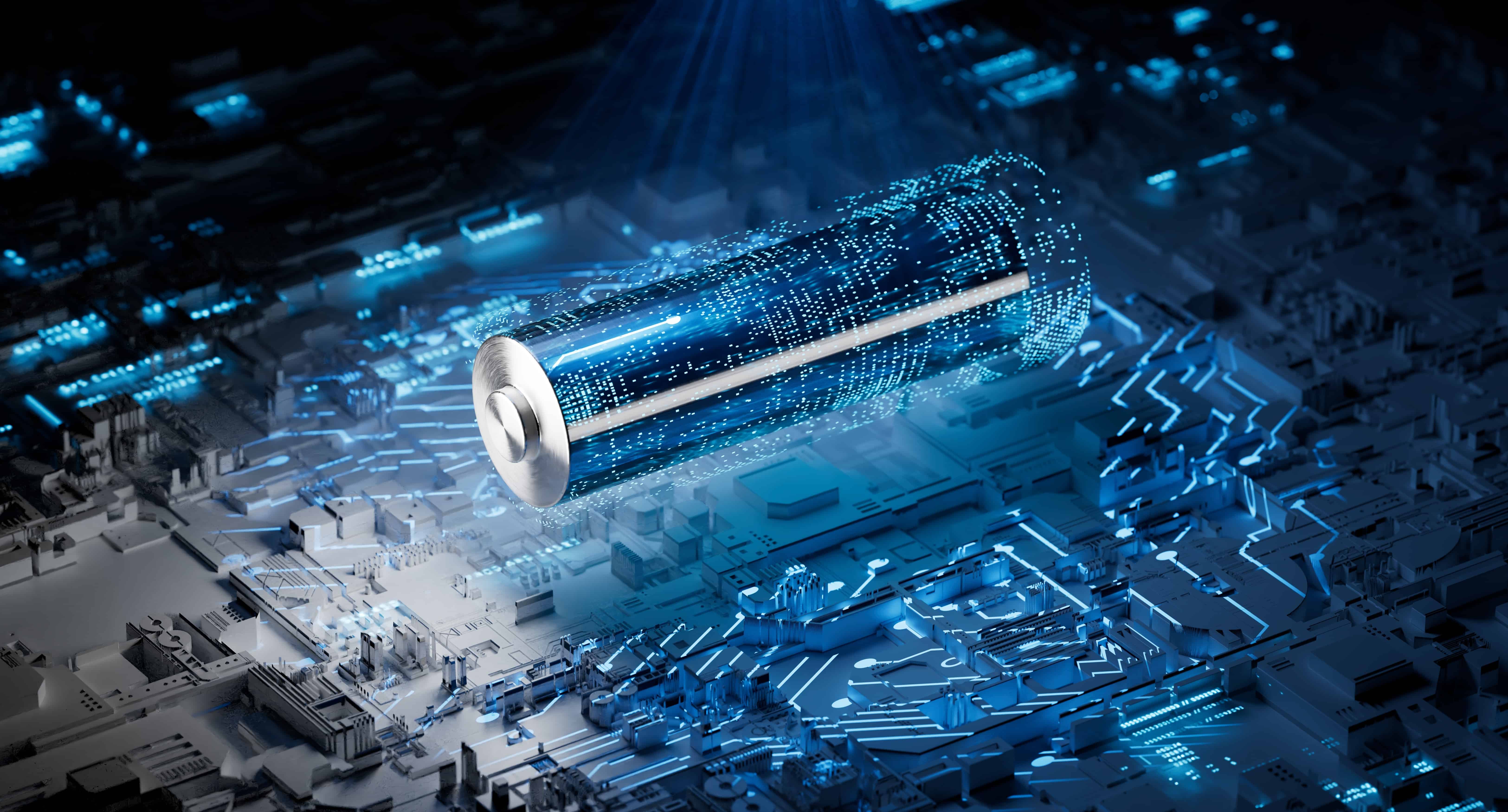

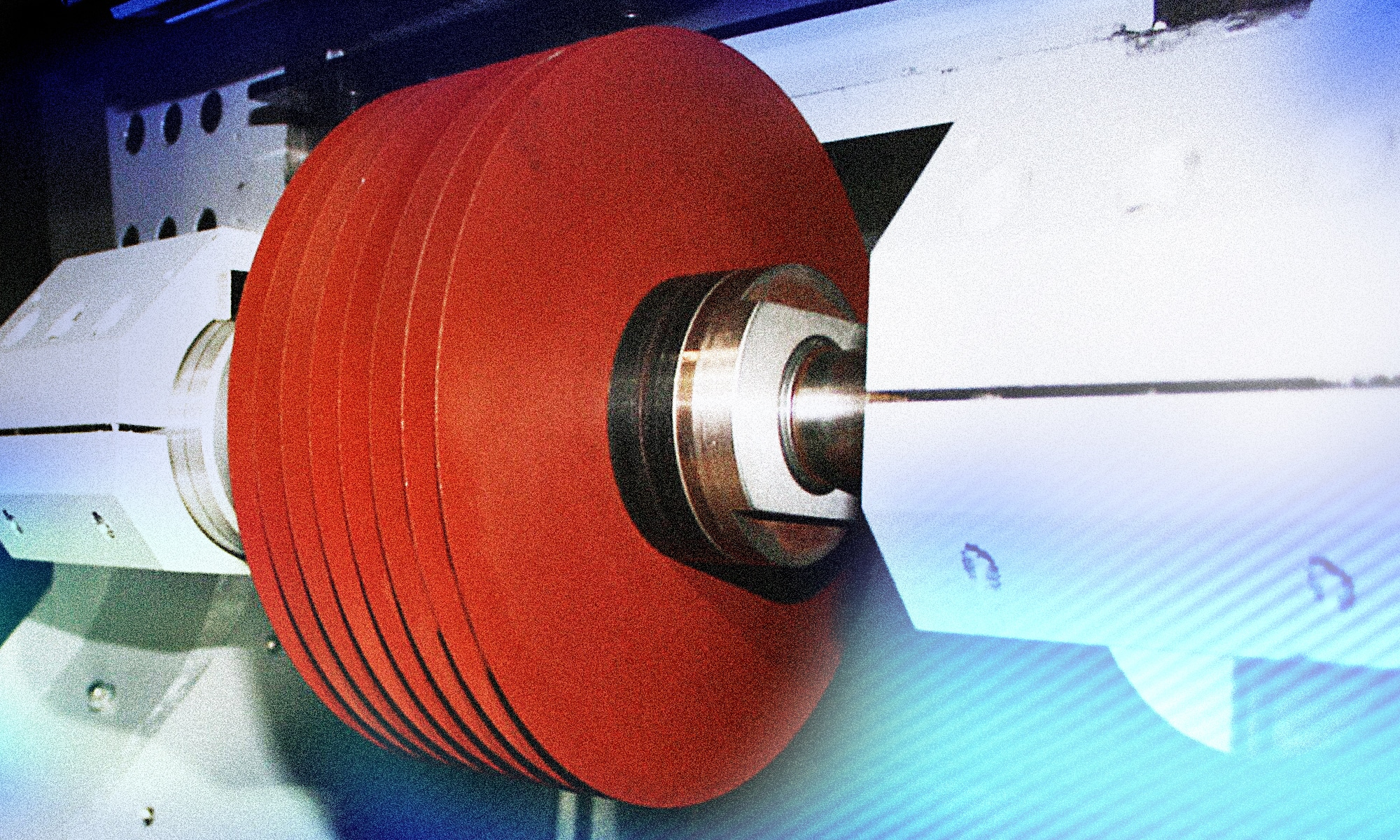

Dicing heat sinks involves the precision cutting or machining of heat sink materials into specific shapes and dimensions. Heat sinks are crucial components in electronic devices that help dissipate heat generated by electronic components, ensuring efficient thermal...

by Steve Rovinsky | Apr 10, 2024 | Uncategorized

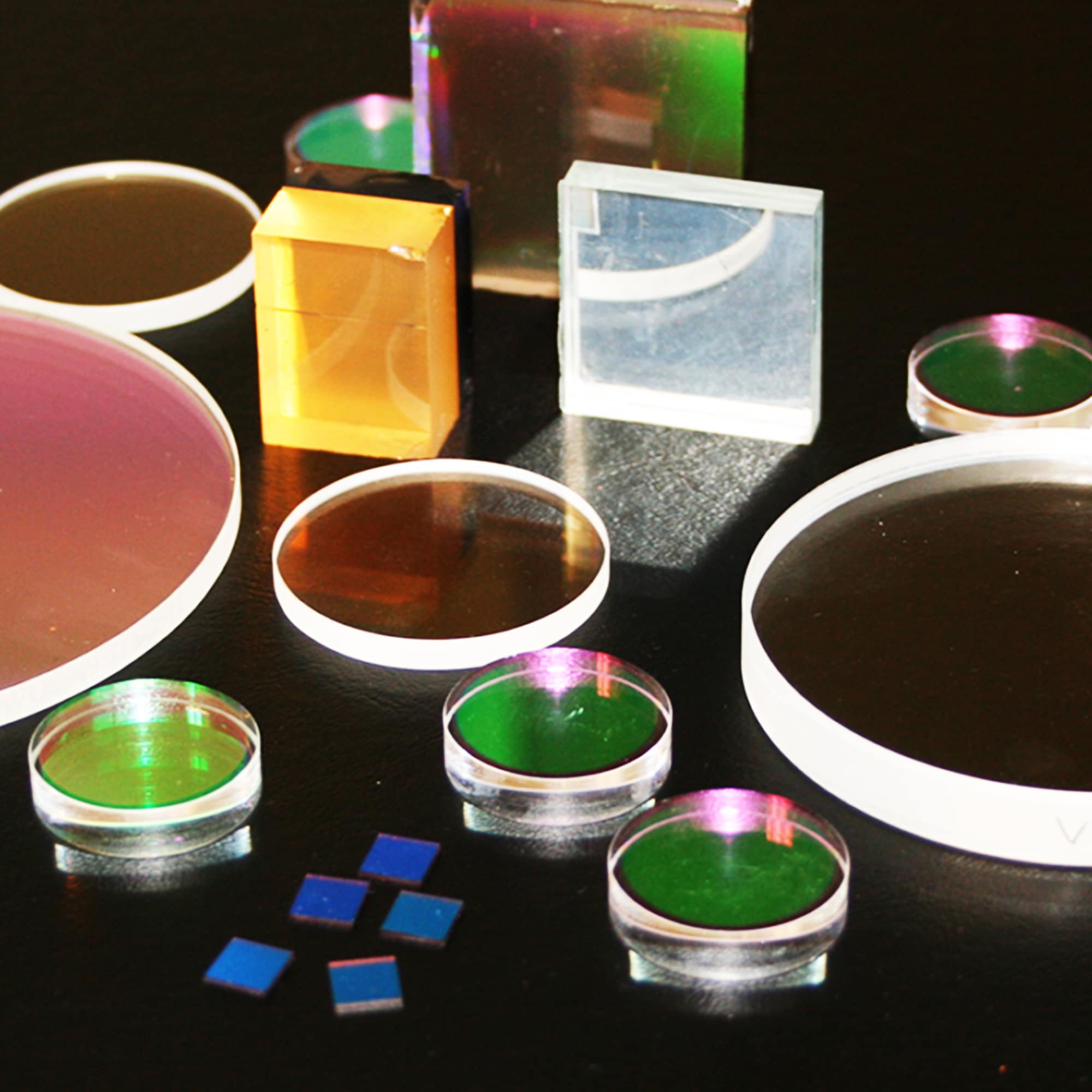

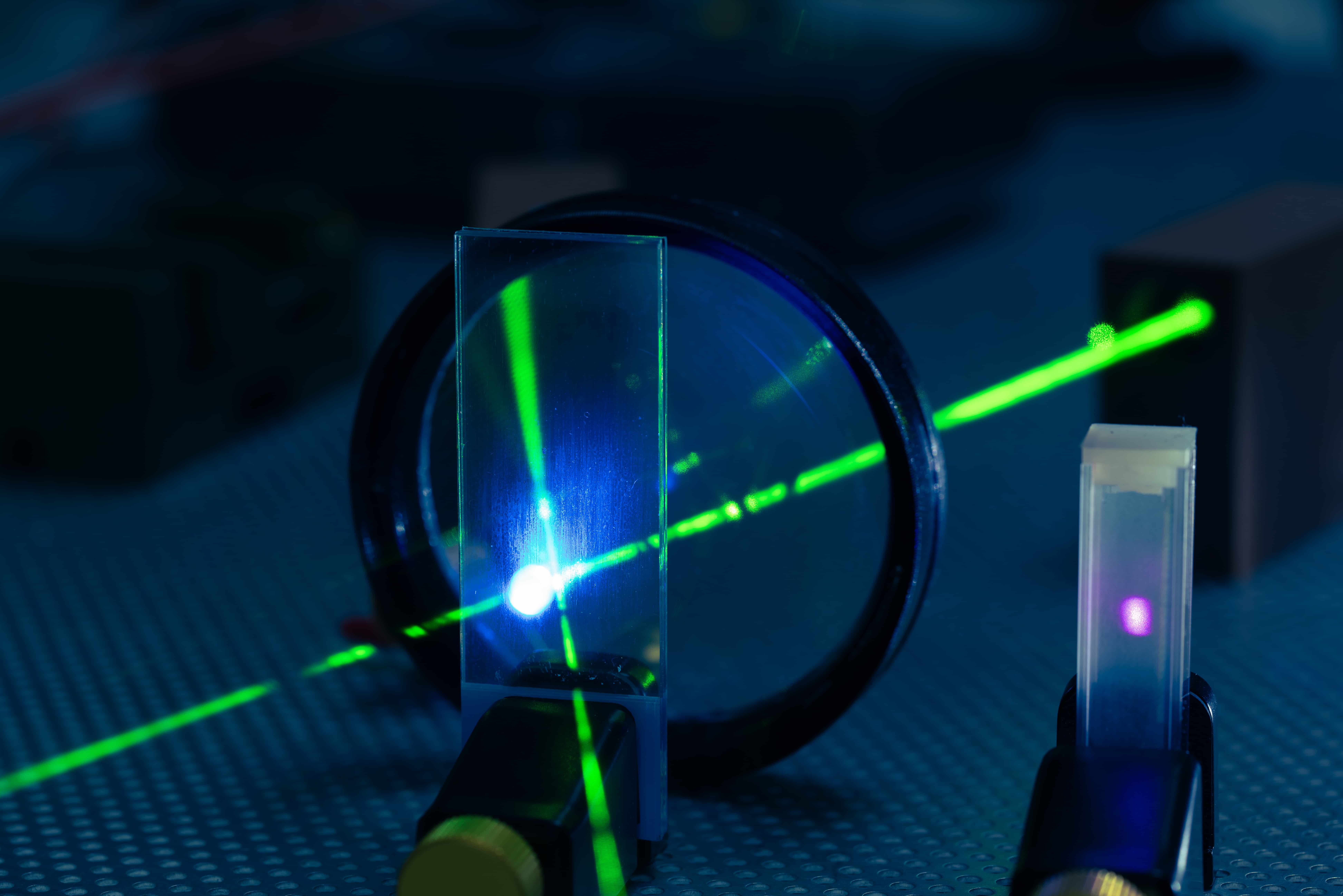

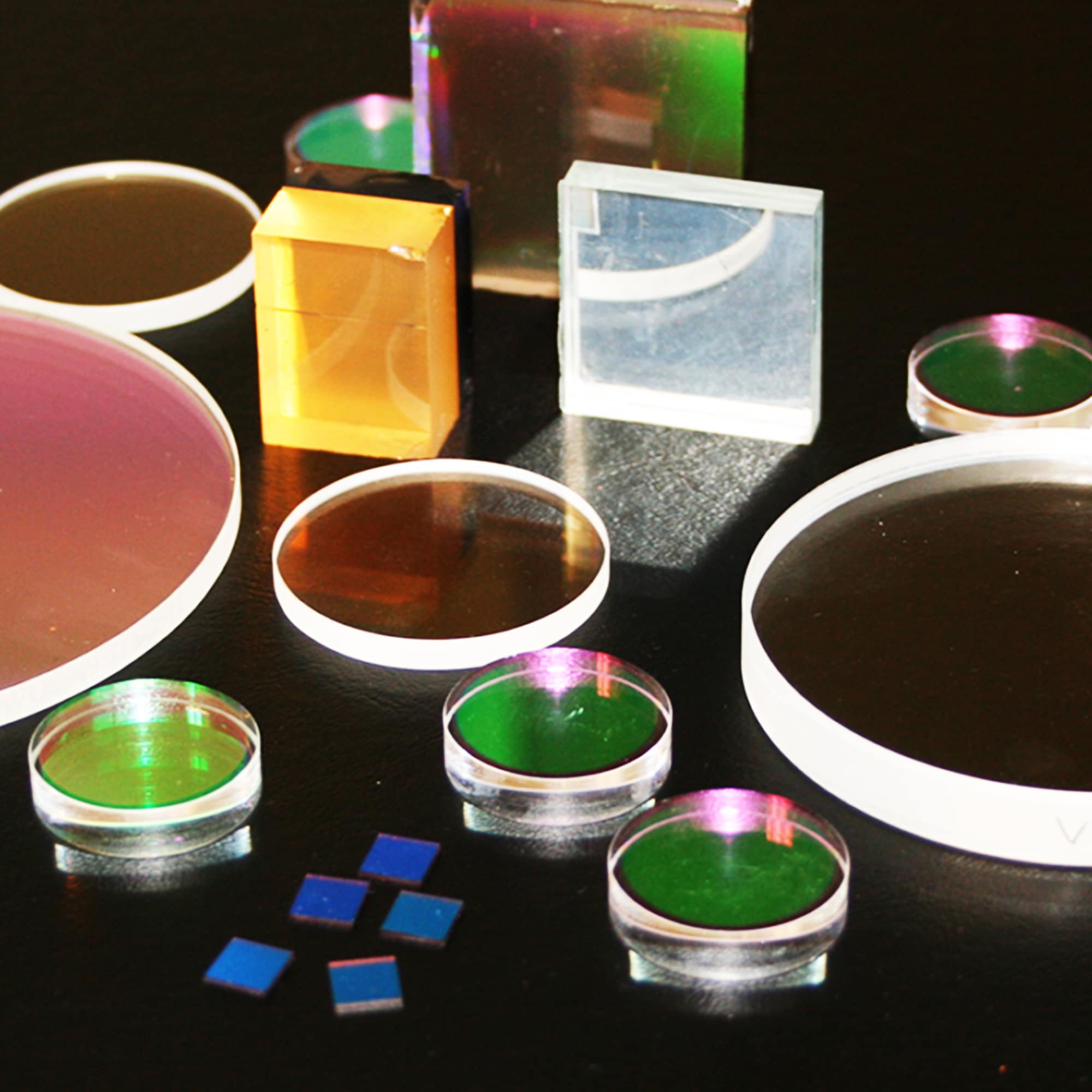

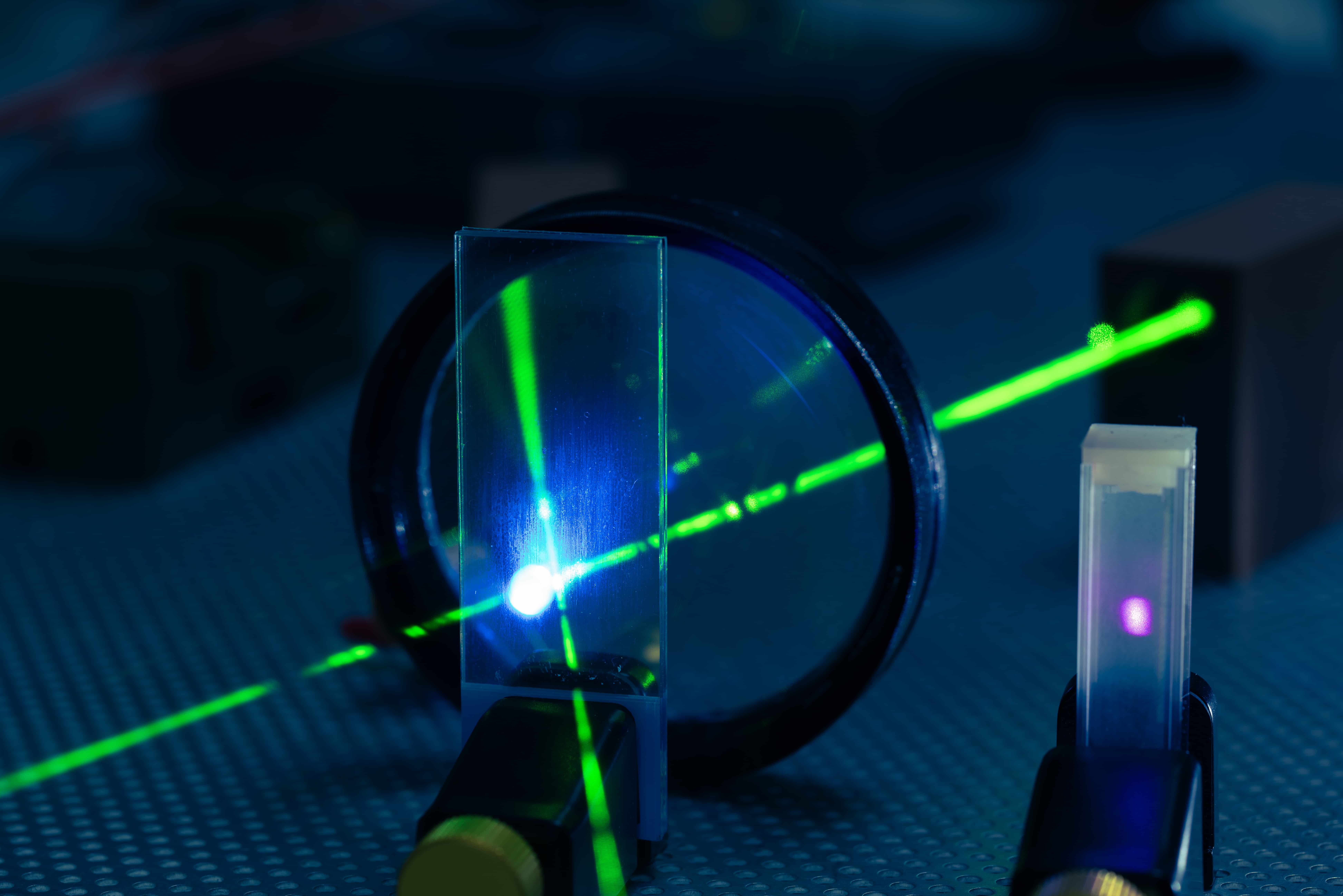

Gang dicing BK7 and lithium niobate involves the simultaneous cutting or separation of multiple optical components made from these specific materials. BK7 is a borosilicate crown glass often used for optical components, while lithium niobate is a crystalline material...

by Steve Rovinsky | Apr 10, 2024 | Uncategorized

ZeroDur” likely refers to a type of glass or glass-ceramic material. Schott AG, a German glass manufacturer, produces a glass-ceramic material known as “Zerodur.” Zerodur is a highly specialized glass-ceramic with extremely low thermal expansion...

by Steve Rovinsky | Apr 10, 2024 | Uncategorized

Gang dicing optics involves the simultaneous cutting or separation of multiple optical components from a larger substrate, often referred to as a wafer. This process is crucial in the production of individual optical devices, lenses, or components used in various...

by Steve Rovinsky | Apr 10, 2024 | Uncategorized

Miniaturization and Integration: The demand for smaller and more compact optical devices is increasing across various industries, such as consumer electronics, healthcare, and telecommunications. Optics manufacturers are focusing on developing miniaturized components...

by Steve Rovinsky | Apr 10, 2024 | Uncategorized

Gang dicing of fused silica involves simultaneously cutting or separating multiple optical components made from fused silica material. Fused silica is a high-purity form of glass that consists of silicon dioxide (SiO2). It possesses exceptional optical properties,...